About Us

Vegnar GFRP is a leading manufacturer of high-quality Glass Fiber Reinforced Polymer (GFRP) composite reinforcement products in Gujarat, India. We supply IS 18256 certified GFRP rebar (straight and bent), mesh/grids, and custom composite profiles for civil infrastructure, marine, industrial, and specialty construction applications. As a trusted TMT steel alternative supplier, our priority is to combine advanced pultrusion technology, precise manufacturing, and rigorous quality control to deliver durable, corrosion-resistant reinforcement solutions with 100+ years lifespan.

Vision & Mission

Vision

To be a global leader in composite reinforcement, championing durable, sustainable, high performance infrastructure.

Mission

- • Produce GFRP products that resist corrosion, reduce maintenance, and enhance life span of concrete structures.

- • Maintain strict quality control (multi-stage QC) to ensure consistency and reliability.

- • Serve clients across infrastructure, marine, industrial, and building sectors with technical support, custom design, and timely delivery.

- • Advance sustainable construction by replacing conventional materials where GFRP offers clear long-term benefits.

Tackling Corrosion

in India's Infrastructure

Corrosion is a silent threat to India's infrastructure, damaging bridges, highways and industrial structures exposed to humidity, saline air and pollutants. It leads to costly repairs, structural failures and environmental strain, compromising safety and longevity.

The Cost of Corrosion

- Economic Impact: Corrosion leads to frequent repairs, increased maintenance costs, and reduced service life of structures. It is estimated that India loses significant GDP annually due to corrosion-related damages.

- Safety Concerns: Structural degradation caused by corroding steel poses significant risks to public safety, with incidents of collapses and failures increasingly common.

- Environmental Fallout: Repeated repairs and replacements consume additional resources, adding to the environmental burden.

The Urgent Need for a Corrosion-Resistant Solution

Traditional steel reinforcement, though strong and versatile, is vulnerable to corrosion, especially in coastal, marine and chemically aggressive environments. To safeguard India's infrastructure and ensure its longevity, the industry needs a material that combines strength, durability and corrosion resistance.

What are

GFRP Rebars?

Glass Fibre Reinforced Polymer Rebars, also known as GFRP Rebars, are a cutting-edge alternative to traditional steel reinforcement in modern construction in India. These are made up of Glass fibre & Resin.

GFRP Rebars have been developed as a non-corrosive solution for reinforcement. They offer superior resistance to chemical degradation in harsh environments like coastal areas, chemical industries and water infrastructure.

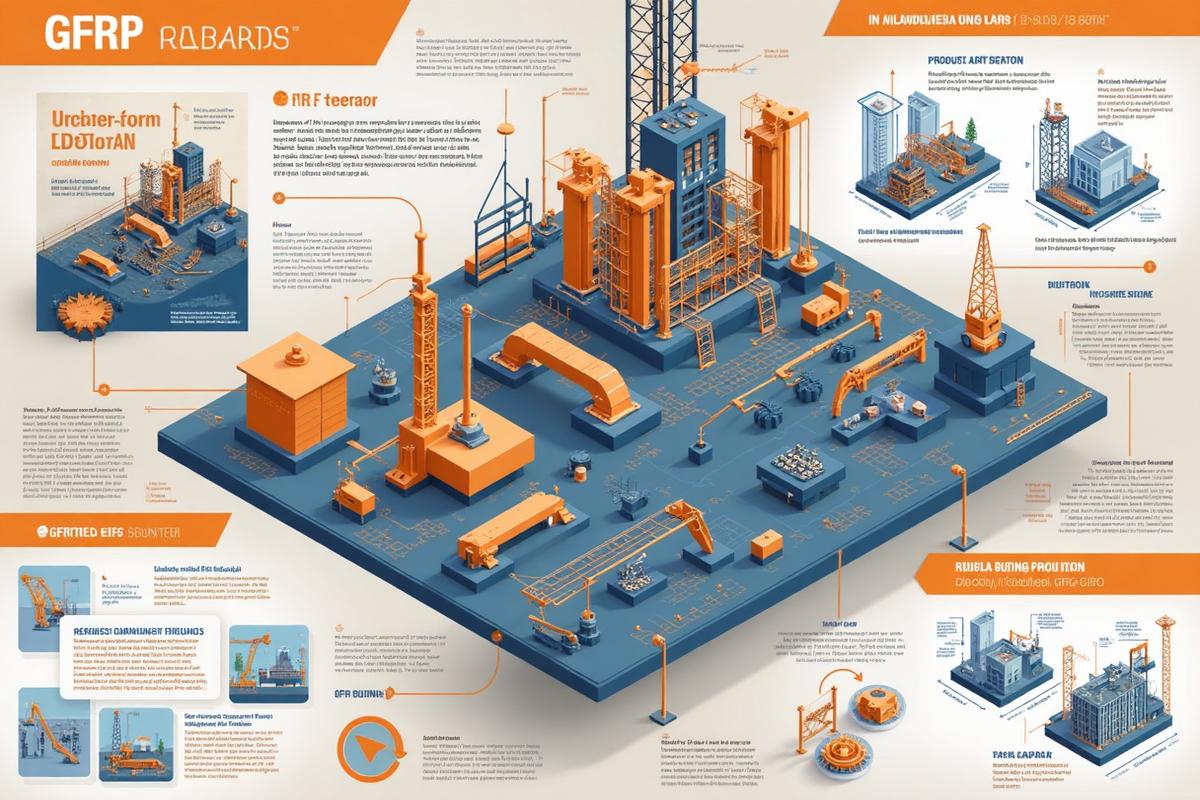

Manufacturing Process

Manufactured through a highly controlled pultrusion process

Continuous glass fibres are drawn from spools and passed through a resin bath, where they are coated with a polymer matrix, typically made of vinyl ester or epoxy.

The resin-coated fibre bundle is then pulled through a heated die, which shapes it into the required profile and initiates the curing process of the resin around the fibres.

The die also initiates the curing process, where heat solidifies the resin to form a rigid, solid composite material.

Once the curing is complete, the GFRP rebar is cut to the desired lengths and surface-treated to enhance bonding with concrete.

Bend | Pre-degree bend | Hook bend | 45 degree bend | S-Bend | U-Bend | Offset Bend

* Note: Actual weight may vary as per tolerance.

Our Technical Excellence

Advanced capabilities ensuring superior GFRP products

Advanced Pultrusion

Continuous fiber reinforcement process ensuring consistent quality and superior mechanical properties

Quality Testing

In-house testing facility for tensile strength, durability, and performance validation

Quality Control

Comprehensive quality assurance protocols meeting international standards

Custom Solutions

Tailored GFRP products designed for specific application requirements